Product Overview

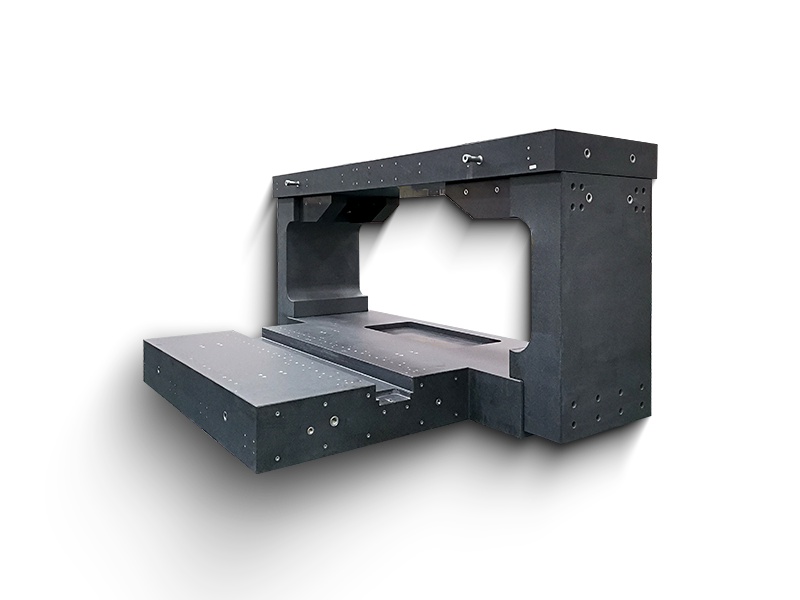

We specialize in manufacturing ultra-stable granite structural components for three-axis motion systems. As granite machining experts, we deliver:

- Granite Machine Bases

- Granite Cross Beams

- Granite Support Columns

Note: We provide structural granite components only – motion systems require third-party drive integration.

Why Granite?

Our natural granite components (Type G350/G650) offer unmatched stability:

- Thermal Neutrality: 0.003 mm/m·°C expansion coefficient (1/30th of steel)

- Vibration Absorption: Q-factor <100 (10x better than aluminum alloys)

- Micro-deformation Resistance: Young’s modulus 60-100 GPa

- Wear-free Operation: Mohs 6-7 hardness surface

Technical Specifications

| Parameter | Specification |

|---|---|

| Material Grades | Black Galaxy G350, Absolute Black G650 |

| Standard Sizes | 400×400mm to 3000×2000mm |

| Geometric Accuracy | ±5μm/m (ISO 10791-1 compliant) |

| Surface Flatness | ≤3μm/m² (laser-verified) |

| Thread Tolerance | 6H/6g (ISO 965-1 standard) |

| Lead Time | 15-35 days (project-dependent) |

Custom Fabrication Process

- Drawing Submission – Accepts DWG/STEP/IGES/SLDDRW formats

- DFM Analysis – Free manufacturability review within 48h

- Material Selection – G350 (general precision) / G650 (ultra-high precision)

- CNC Machining – 5-axis milling with ≤2μm positioning repeatability

- Quality Assurance – Includes:

- Laser interferometer calibration

- Dynamic stiffness mapping

- 72-hour thermal cycling test

Typical Applications

- Semiconductor wafer inspection stages

- Aerospace CMM mounting platforms

- Photolithography equipment bases

- Laser interferometer reference beds

- Optical alignment systems

Competitive Advantages

✓ Component Specialization – 100% focus on granite structural elements

✓ No MOQ – Prototype to production quantities

✓ Dual Certification – ISO 9001:2015 & AS9100D compliant

✓ Global Logistics – Experienced in sensitive equipment packaging