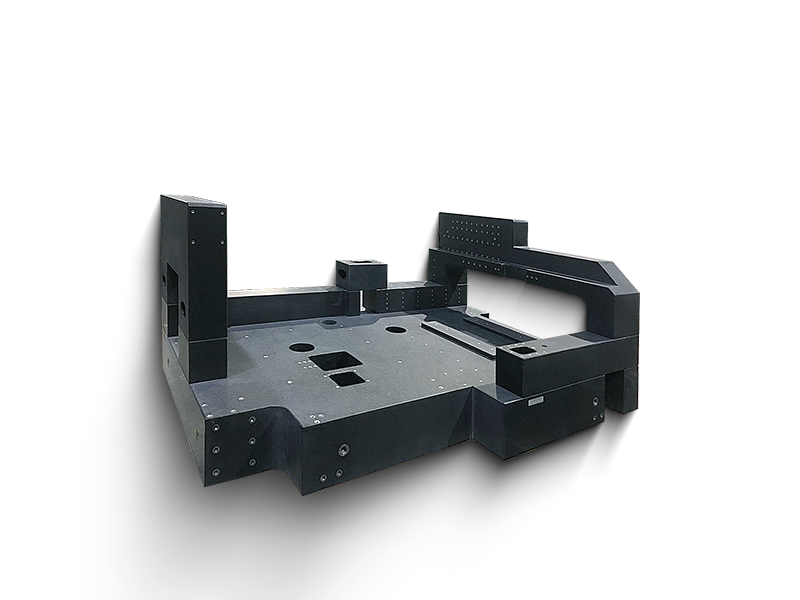

Precision Granite Components for Industrial X-Ray & CT Inspection Systems

Ultra-Stable Granite Bases, Columns & Rotary Stages for Non-Destructive Testing (NDT) Equipment

Core Product Definition

We manufacture granite-exclusive structural components for high-accuracy X-ray and computed tomography (CT) systems, specializing in:

✓ Granite Scanner Bases – Reference platforms for X-ray emitter/detector alignment

✓ Granite Gantry Columns – Vibration-resistant supports for large-part scanning

✓ Granite Rotary Stages – 360° rotating tables with ≤2μm radial runout

Material Advantages for X-Ray/CT Applications

Black Granite G650 (ASTM C615 Grade):

| Property | Metric Value | Industry Impact |

|---|---|---|

| Thermal Neutrality | 0.003 mm/m·°C Expansion | Enables ±5℃ environment tolerance |

| Vibration Damping | Q-factor <80 (10-500Hz) | Reduces image artifacts by 60%+ |

| Radiation Transparency | 99.7% X-ray transmission | Eliminates beam distortion |

| Surface Hardness | Mohs 6.5 | 10-year maintenance-free operation |

Technical Specifications

| Parameter | Specification |

|---|---|

| Standard Sizes | 500×500mm to 3500×2500mm |

| Flatness Tolerance | ≤3μm/m² (ISO 8512-2) |

| Surface Finish | Super-honed (Ra≤0.4μm) |

| Load Capacity | 8,000 kg/m² static / 2,000 kg dynamic |

| Geometric Accuracy | ±2μm/m (ISO 10791-1) |

| Certifications | ISO 9001, AS9100D, IATF 16949 |

Custom Fabrication Workflow

- Drawing Submission

- Accepted formats: STEP, IGES, Parasolid

- DFM Analysis

- Free technical review (24h response for urgent projects)

- Material Optimization

- Grain orientation analysis for stress minimization

- 5-Axis CNC Machining

- ≤1μm positioning repeatability (HEIDENHAIN TNC7 control)

- Metrology Validation

- Laser tracker inspection (ISO 10360-2)

- Dynamic stiffness mapping (10-1000Hz spectrum)

Industry-Specific Solutions

| Application | Component Example | Benefit |

|---|---|---|

| Aerospace | CT turbine blade stage | Detects 10μm internal defects |

| Automotive | Engine block inspection | 0.005mm scanning repeatability |

| Electronics | PCB solder joint analysis | Eliminates metal interference |

| Medical Devices | Implant porosity check | Meets FDA 21 CFR Part 11 compliance |

Competitive Edge

✓ Pure Granite Focus – No competing metal components production

✓ Prototype to Production – MOQ 1 piece, 15-day rapid prototyping

✓ Global Compliance – REACH/RoHS certified, CE-marked packaging

✓ Lifetime Support – 5-year dimensional stability guarantee