The granite precision platform (also known as a granite precision platform) is a high-precision measurement reference tool crafted from natural granite or granite. Widely used in industrial manufacturing, laboratory testing, and precision instrument calibration, it outperforms traditional metal platforms (e.g., cast iron) due to its exceptional physical properties.

I. Core Features

- Exceptional Stability

- Natural stone formed over millions of years ensures internal stress is fully released, minimizing deformation risks.

- Extremely low thermal expansion coefficient (about 1/3 of cast iron), maintaining dimensional stability under temperature fluctuations.

- High Hardness & Wear Resistance

- Mohs hardness of 6–7 (granite), resistant to scratches, with minimal long-term accuracy loss.

- Corrosion Resistance & Insulation

- Resistant to acids, alkalis, rust, and non-conductive, suitable for humid or chemical environments.

- Superior Vibration Damping

- High natural damping coefficient absorbs mechanical vibrations, reducing measurement errors.

II. Manufacturing Process

- Material Selection

- High-quality natural granite or granite (e.g., Jinan Black, Mount Tai Black) with uniform color and no cracks.

- Rough Machining & Shaping

- Cutting: Slabs are cut to design dimensions.

- Rough Grinding: Initial shaping to approximate geometry.

- Manual Precision Grinding

- Semi-Fine Grinding: Removes rough marks, achieving flatness of 0.02–0.05 mm/m.

- Hand Polishing: Multi-step grinding (using diamond sand, resin discs) to achieve micron-level accuracy.

- Precision Verification & Adjustment

- Flatness and straightness tested with electronic levels or laser interferometers.

- Stabilized in a controlled environment (20±1°C) for 24 hours, followed by recalibration.

- Surface Polishing & Protection

- Polished to surface roughness Ra ≤ 0.2 μm to reduce friction.

- Coated with stone sealant for enhanced stain and water resistance.

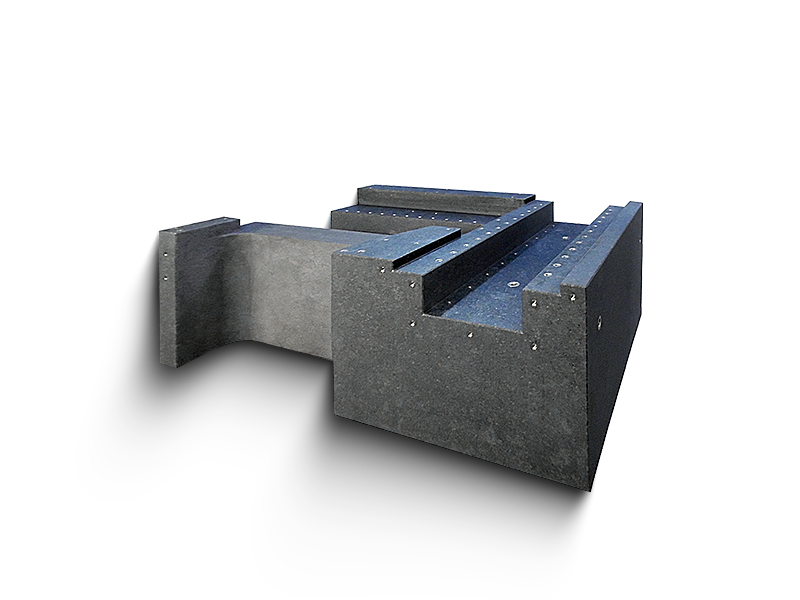

- Functional Machining

- Drilling holes, milling slots, and embedding metal components (e.g., threaded sleeves, dowel pins).

III. Accuracy Grades & Standards

| Grade | Flatness Tolerance (μm/m) | Applications |

|---|---|---|

| 000 | ≤1.5 | Ultra-high-precision metrology, optical instrument calibration |

| 00 | ≤3.0 | Precision part inspection, CMM reference |

| 0 | ≤6.0 | Industrial inspection, machine tool alignment |

Complies with GB/T 20428-2006 “Rock Surface Plates” standard.

IV. Key Applications

- Precision Measurement

- Coordinate Measuring Machine (CMM) bases, laser interferometer platforms.

- Machinery Manufacturing

- Machine tool beds, spindle mounting reference surfaces.

- Electronics Industry

- Semiconductor wafer inspection, lithography machine platforms.

- Scientific Research

- Optical experiment platforms, vibration testing tables.

V. Usage & Maintenance Guidelines

- Installation Environment

- Avoid direct sunlight and temperature extremes; ideal ambient temperature: 20±2°C.

- Mount on vibration-isolated foundations or tables to block external vibrations.

- Routine Care

- Clean regularly with neutral detergent and soft cloths; avoid acidic cleaners.

- Cover with anti-dust sheets when not in use.

- Accuracy Recalibration

- Check flatness every 6–12 months using electronic levels; regrind if necessary.

VI. Advantages Over Cast Iron Platforms

| Criteria | Granite Platform | Cast Iron Platform |

|---|---|---|

| Thermal Stability | Minimal thermal deformation | Prone to thermal distortion |

| Maintenance Cost | Rust-free, long-term maintenance-free | Requires rust-proof oil and scraping |

| Lifespan | 20+ years | 10–15 years (frequent upkeep) |

| Environment Suitability | Humid, non-magnetic, chemical settings | Primarily dry environments |

VII. Selection Recommendations

- Accuracy Needs: Prioritize Grade 000 or 00 for high-precision tasks.

- Size Matching: Platform area should exceed 1.5x the measured object’s size.

- Future-Proofing: Include threaded holes, T-slots, etc., for modular tooling.

By selecting and using granite precision platforms appropriately, they serve as reliable foundations for industrial precision control, significantly enhancing product quality and production efficiency.