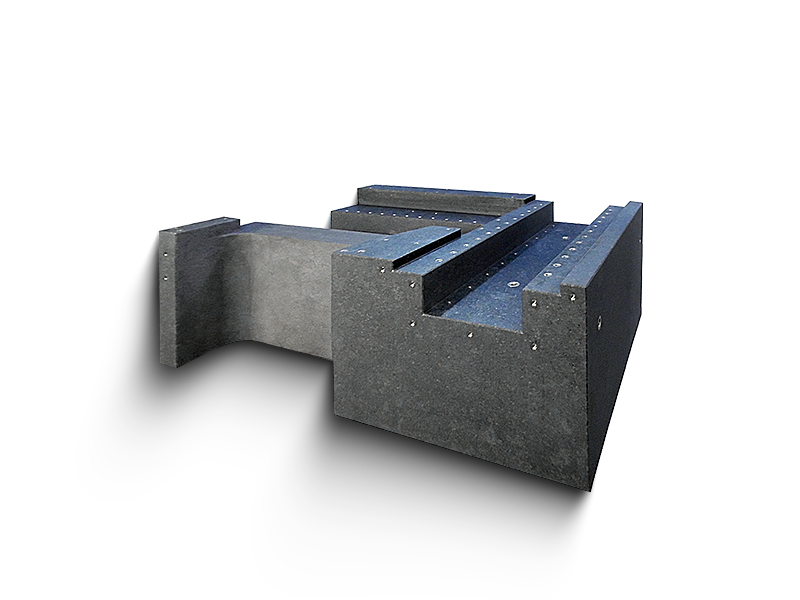

High-Precision Granite Machine Components

Custom-Engineered for Stability & Vibration Resistance

✓ ISO 9001-Certified Granite Components

✓ ±0.003mm/m² Ultra-Tight Tolerance

✓ 30+ Years in Precision Machining

✓ CAD/CAM Customization Available

| Property | Specification |

|---|---|

| Material Grade | Class-A Granite (DIN 876 Standard) |

| Surface Flatness | ≤1.5μm/m² |

| Thermal Expansion | 4.5×10⁻⁶/°C (20-50°C) |

| Standard Sizes | 300x300mm to 2000x4000mm |

| Lead Time | 15-30 Days with CAD Files |

1. Granite Material Properties

Our granite machine components are machined from stress-relieved Class-A granite, ensuring near-zero porosity and natural vibration damping. Each block undergoes:

3-Step CNC Surface Grinding (Roughing, Semi-Finishing, Mirror Finish)

Laser Interferometry Calibration (Traceable to NIST Standards)

Non-Destructive Testing (Ultrasonic Flaw Detection)

2. Industrial Use Cases

Engineered for mission-critical applications:

CNC Machine Bases: Reduce thermal drift by 60% vs. steel

CMM Measuring Platforms: Achieve ANSI B89.3.7 compliance

Semiconductor Wafer Stages: 99.97% vibration isolation

Optical Alignment Systems: Microradian-level angular stability

3. Pain Point Solutions

By choosing our granite components:

↑ 30% Machining Accuracy through inherent dimensional stability

↓ 45% Maintenance Costs with non-corrosive granite surfaces

✓ 5-Year Warranty backed by AS9100D aerospace certification

4. Custom Granite Parts

Step 1 – Upload your CAD drawing (IGES/STEP/DWG)

Step 2 – Receive DFM analysis within 24hrs

Step 3 – Prototype delivery in 10-15 working days

Step 4 – Full production with real-time QC reports