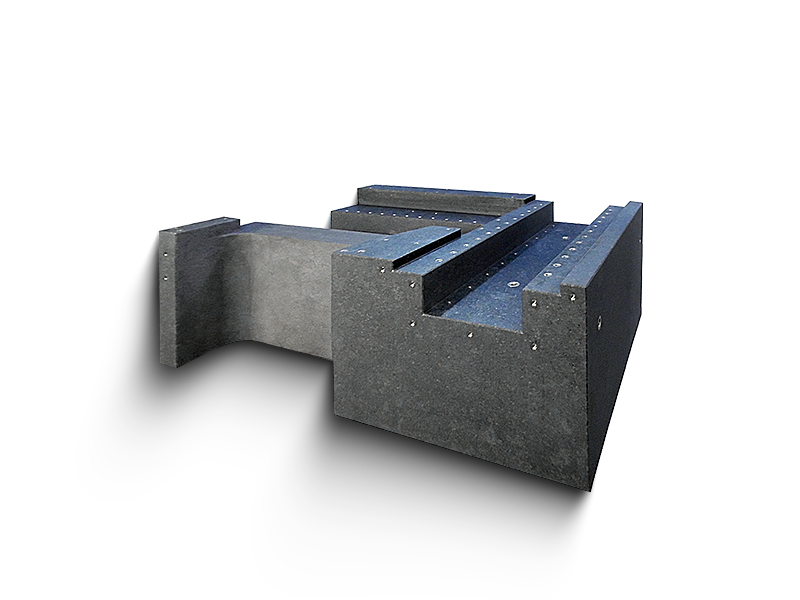

Granite mechanical components are precision-engineered from high-quality natural granite through mechanical processing and manual fine grinding. Characterized by a black luster, uniform texture, and exceptional stability, these components exhibit high strength, hardness, and resistance to rust, magnetization, deformation, and wear. They maintain stability under heavy loads and normal temperatures, making them ideal for industrial and laboratory measurement applications.

Key Features and Applications

- Dimensional Accuracy: Strict tolerance control (within 1mm) for external dimensions.

- Functional Adaptability: Surfaces may require countersunk holes, through-holes, slots, etc., tailored to integrate with other equipment.

- Versatility: Essential for inspection, measurement, machining, and testing across industries such as machinery manufacturing, electronics, and aerospace.

- Common Uses:

- Measurement and calibration of machine tools.

- Inspection of dimensional accuracy and geometric tolerances.

- Workbench for (layout), welding, tooling, and vibration testing.

- Common Uses:

Machining Process Overview

Granite mechanical components are custom-manufactured based on technical drawings. The process involves the following stages:

- Material Selection

- Select raw granite slabs matching the design specifications (dimensions and properties).

- Cutting

- Cut slabs to required lengths, widths, and thicknesses using precision tools.

- Rough Grinding

- Initial shaping to achieve approximate dimensions and flatness.

- Semi-Fine Grinding

- Remove deep scratches and refine flatness.

- Fine Grinding

- Manual precision grinding to enhance dimensional and geometric accuracy.

- Polishing

- Achieve a smooth, low-roughness surface to minimize wear and stabilize precision.

- Feature Machining

- Drill holes (countersunk, through-holes), install steel sleeves, or mill slots as per drawings.

- Precision Verification

- Use electronic levels or laser measuring tools to validate flatness, parallelism, and perpendicularity.

- Post-Machining Adjustments

- After initial calibration, components are stabilized for 12 hours and rechecked. Adjustments are repeated until specifications are met.

- Final Inspection

- Compare finished components against drawings to ensure compliance with tolerances and functional requirements.

Customization and Quality Control

- Design Flexibility: Components may be tailored to user-specific needs, balancing cost-effectiveness with performance.

- Collaborative Optimization: Designs prioritize mutual benefits for both manufacturers and end-users.

- Stability Assurance: Crystallization hardening and waterproofing treatments enhance durability and stain resistance.

Advantages Over Traditional Materials

Granite outperforms cast iron in high-precision measurement scenarios due to its inherent properties:

- Thermal Stability: Minimal expansion/contraction under temperature fluctuations.

- Vibration Damping: Reduces measurement errors caused by external vibrations.

- Long-Term Precision: Maintains accuracy over decades with minimal maintenance.